minutes average completion time

The supply chain

In this micro course, we will explore the different functions required to keep a supply chain running smoothly as goods and services travel the globe. We will also look at just a few of the exciting opportunities and careers that exist within a supply chain.

What is a Supply Chain?

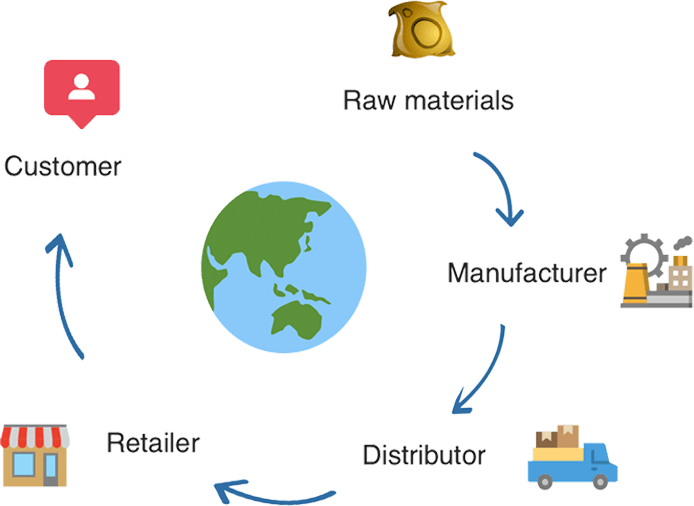

A supply chain is a network of companies and people that are involved in the production and delivery of a product or service.

This can be represented as a sequence from suppliers and manufacturers through to distributors to retailers before reaching the end customer.

Each of these stages must be managed to carefully balance supply with demand.

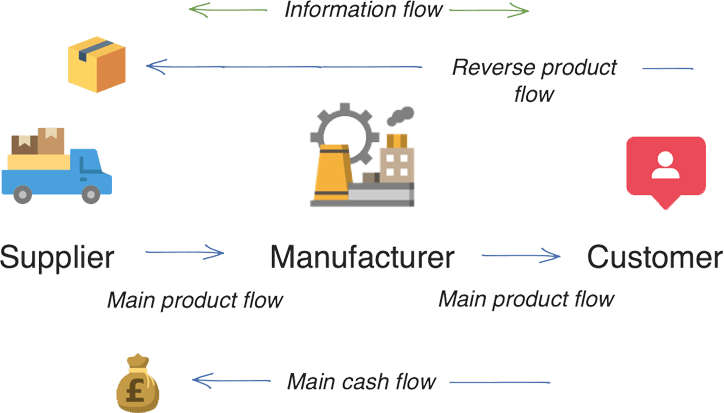

The movement of work around a supply chain can be referred to as ‘flow’. Supply chains aim to have a ‘good flow’, which means that everything is moving steadily and predictably.

There are 3 main flows in a supply chain:

- Product flow: This describes the movement of products from the supplier to the customer along with the flow of returned products.

- Information flow: This describes the communication of information, including the transmitting of orders and updating the status of delivery.

- Financial flow: This describes the movement of money, which mainly flows backwards from the customer.

We can see how this might look in practice by using the diagram below.

For example, there will be occasions when customers’ needs have not been met, resulting in the need for goods to be returned. Managing returns is never quite as simple as putting items back on a shelf to be shipped off to another customer – and it requires a lot of resource.

You might notice that flow in a supply chain does not only happen in one direction.

Information must also flow in both directions. Information has no physical presence, unlike facilities, transportation, and inventory, but its value to the supply chain must not be underestimated.

Without effective communication and technology, it would be impossible for a supply chain to operate effectively.

Companies know this and during 2024 half of supply chain organisations are expected to invest in artificial intelligence (AI) and advanced data programmes.

Whether it is manufacturing, planning, marketing, distribution, or retail: at every stage are people with a specific set of skills that together make up a functioning supply chain.

In this book, we will explore just some of the functions involved in supply chains and some of the opportunities within them.

Did you know?

In the UK, £600 million worth of goods are returned over the Black Friday weekend alone!

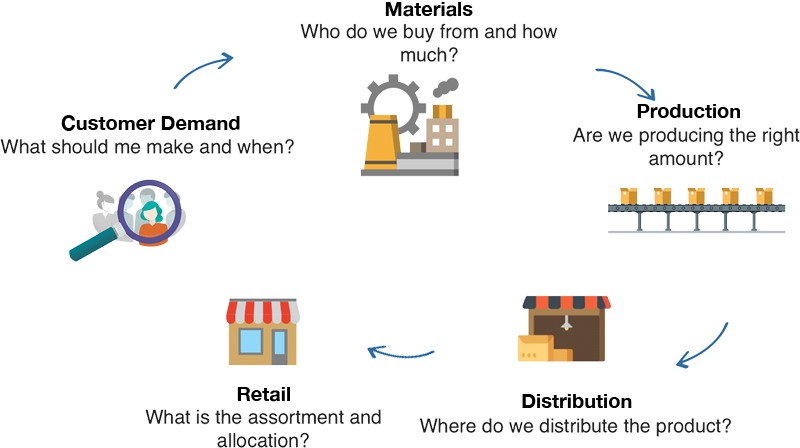

Supply Chain Operations: Planning

Supply chain planning involves anticipating the demand for products and planning their materials, production, marketing, and sale.

When used in an economic context, ‘demand’ refers to a customer’s desire to purchase goods and services and willingness to pay a specific price for them.

Forecasting

Supply chains use a technique called forecasting to help predict future customer demand.

This allows companies to make and stock enough product to meet the expected demand and avoid upsetting customers by being out of stock. It also helps to prevent companies from making and stocking too many products that do not sell and costs the company in storage.

A forecast is a prediction of future events using a means other than making a guess. It is a process that uses historical sales data to estimate future customer demand.

Forecasting is an essential part of planning and can be found everywhere in supply chains.

Customer demand is not always consistent so forecasts must be revised frequently.

Demand varies for many reasons and effective forecasting depends on understanding these trends. Common influences on demand include:

- Market trends

- Seasonal factors

- Weather

- Competitor activity

Click on the images below to learn about the influences on demand

Companies use lots of data and can end up with many different forecasts. This information must all be collected to create one overall plan.

This process is called sales and operations planning (S&OP) and involves a range of people who work in sales, finance, and operations.

The plan created during this process is used to create objectives that everyone in the company can then help to achieve.

Example careers in Supply Chain Planning

Click on the buttons below to learn about some of the different roles in Supply Chain Planning…

Did you know?

Forecasts can span for many years but tend to become less accurate the longer they are.

Make a note!

Find a statement that best describes forecasting.

Market Trends

Trends are an upward or downward movement in demand. When products experience a growth or decline in the market, trends tend to emerge.

An example would be the decreased demand for paper-based books as the use of e-Books increase.

Seasonal Factors

‘Holiday shopping’ is something that retailers can safely rely on anywhere in the world.

Holidays that drive traffic across Europe include:

Christmas

Valentine’s Day

New Year’s Eve

Summer holidays

Weather

Weather is a critical driver of product demand. The most heavily affected industries are:

Food and drinks

Pharmaceutical

Fashion

Competitor Activity

The level of competition in the market affects the accuracy of forecasts.

It is easier to forecast in a less competitive market.

Forecasting becomes more difficult in markets where there are many companies competing for customers.

Supply Planner

Average Salary: £26,000-£38,000 (or £1,3333 – £3,166 per month)

A supply planner develops and executes a plan for a portfolio of items based on demand, actual orders, lead times and available stock.

Data analyst statistician

Average Salary: £23,000-£62,000 (or £1,916 – £5,166 per month)

Data analyst-statisticians collect numbers and statistics to identify trends, create models and present results.

In this role you could:

- Look for trends and patterns to help organisations make decisions.

- Investigate market research into consumer habits and feedback.

- Create models to predict demand for services or goods.

Supply chain manager

Average Salary: £24,000-£48,000 (or £2,000 – £4,000 per month)

Supply chain managers organise the movement of goods and materials from suppliers and manufacturers to customers.

In this role you could:

- Work with procurement managers and buyers to select products that will sell well.

- Negotiate and manage contracts with suppliers.

- Plan the best way to get goods from suppliers to distribution centres and retailers.

- Track shipments and stock levels using computer software.

- Make sure retailers receive their goods on time and in the right condition.

- Look at ways to improve supply chain networks.

- Monitor overall performance to make sure targets are met.

- Prepare forecasts and inventories.

- Recruit, train and manage a team of supply chain staff.

Supply Chain Operations: Sourcing

Sourcing is the choice of who will provide a particular supply chain activity. For example, a company may be looking for someone to supply materials, offer storage, provide transportation, or help manage their data.

Companies take selecting the right suppliers very seriously. Selecting the right suppliers makes a huge difference to the cost and quality of products and services. For example, the material costs of many products can make up 50% of the total manufacturing costs!

Choosing the wrong suppliers (who are unreliable or too expensive) can cause performance levels and customer satisfaction to fall steeply and operational costs to rise rapidly.

Supply chains are made up of functions and professional dedicated to selecting the best suppliers. This type of strategic buying is known as ‘procurement’.

Procurement

Procurement involves sourcing the goods or services needed and negotiating the best prices and terms of service. This often includes visiting suppliers at their offices and factories and can involve international travel.

There might be many suppliers willing to provide the goods or services required, so an important aspect of procurement is shortlisting suppliers.

Questions to consider here include:

Is the price reasonable?

Is it good quality?

Is the supplier reliable?

Does the supplier have a good reputation?

Procurement and the law

Price and reliability are not the only decisions that many companies base their sourcing decisions off.

Buyers have legal obligations to ensure that they take measures to prevent illegal conduct in their supply chains.

For example, the Bribery Act was introduced in 2010 which states that companies can face legal sanctions if their suppliers are found to be involved in corruption or bribery.

Modern slavery occurs in every country in the world and affects almost every industry, although the risks are bigger in places where:

- Workers have few legal protections.

- There are high levels of poverty.

- There is widespread use of migrant workers (who are often treated unfairly).

Supply chains are complex webs that span the world. For example, up to 200 can be involved in the production of a single pair of trainers!

To help combat modern slavery the UK government introduced the Modern Slavery Act in 2015.

This places a legal requirement on large UK companies to produce an annual slavery and trafficking statement. This statement must show the steps they take to ensure that slavery is not taking place in its supply chains.

Customers are also increasingly aware of ethical issues and are supporting (if not demanding) ethical procurement. Organisations will suffer severe reputational damage if they are found to be sourcing from suppliers using modern slavery.

Example careers in Supply Chain Sourcing

Click on the buttons below to learn about some of the different roles in Supply Chain Souring…

Buyer

Buyers choose products for shops to sell, like clothing, toys, electrical goods and food.

Average Salary: £18,000-£50,000 (or £1,500 – £4,1666 per month)

In this role you could:

- Analyse and forecast trends from consumer data.

- Attend trade fairs to find new products.

- Manage product quality.

- Obtain and analyse customer feedback.

- Negotiate prices, orders and delivery dates.

- Present collections to senior managers.

- Track sales figures, manage stock levels and keep to budgets.

- Check and react to competitor activities.

- Adapt quickly to meet changing consumer behaviour and trends.

Finance officer

Finance officers help to manage the finances of an organisation by keeping track of its income and controlling its spending.

Average Salary: £19,500-£34,000 (or £1,625 – £2,833 per month)

In this role you could:

- Record financial transactions on computer systems.

- Produce financial forecasts.

- Deal with payroll, invoices, expenses and VAT.

- Resolve payment questions for external contractors.

- Carry out financial audits.

- Create budget reports.

- Present reports to managers.

Purchasing manager

Procurement managers buy equipment, goods and services for their company or organisation.

Average Salary: £28,000-£60,000 (or £2,333 – £5,000 per month)

In this role you could:

- Identify what goods, services and equipment are needed.

- Draw up tenders and assess bids from potential suppliers.

- Present any legal or commercial risks to senior leadership teams.

- Identify savings, negotiate prices and agree contracts with suppliers.

- Monitor the performance of contracted suppliers.

- Manage a purchasing team and make sure rules are followed correctly.

Did you know?

There are an estimated 30 million people enslaved today and two thirds of these are subjected to forced labour.

Make a note!

Large UK companies must produce an annual slavery and trafficking statement to comply with which Act?

Supply Chain Operations: Manufacturing

Manufacturing is the process in which a company sources raw materials or components and converts them into a finished product.

A raw material is a material before it has been processed for use. This includes materials such as oil, cotton, or sugar.

Example: Manufacturing Glass

Glass is made from natural and abundant raw materials. The exact composition of different types of glass varies, but all glass is made up of the following 3 raw materials:

- Sand.

- Soda ash.

- Limestone.

To make glass, these raw materials are placed together in a furnace where they are melted to form molten glass. The molten glass is then taken out of the furnace to be shaped into its final form.

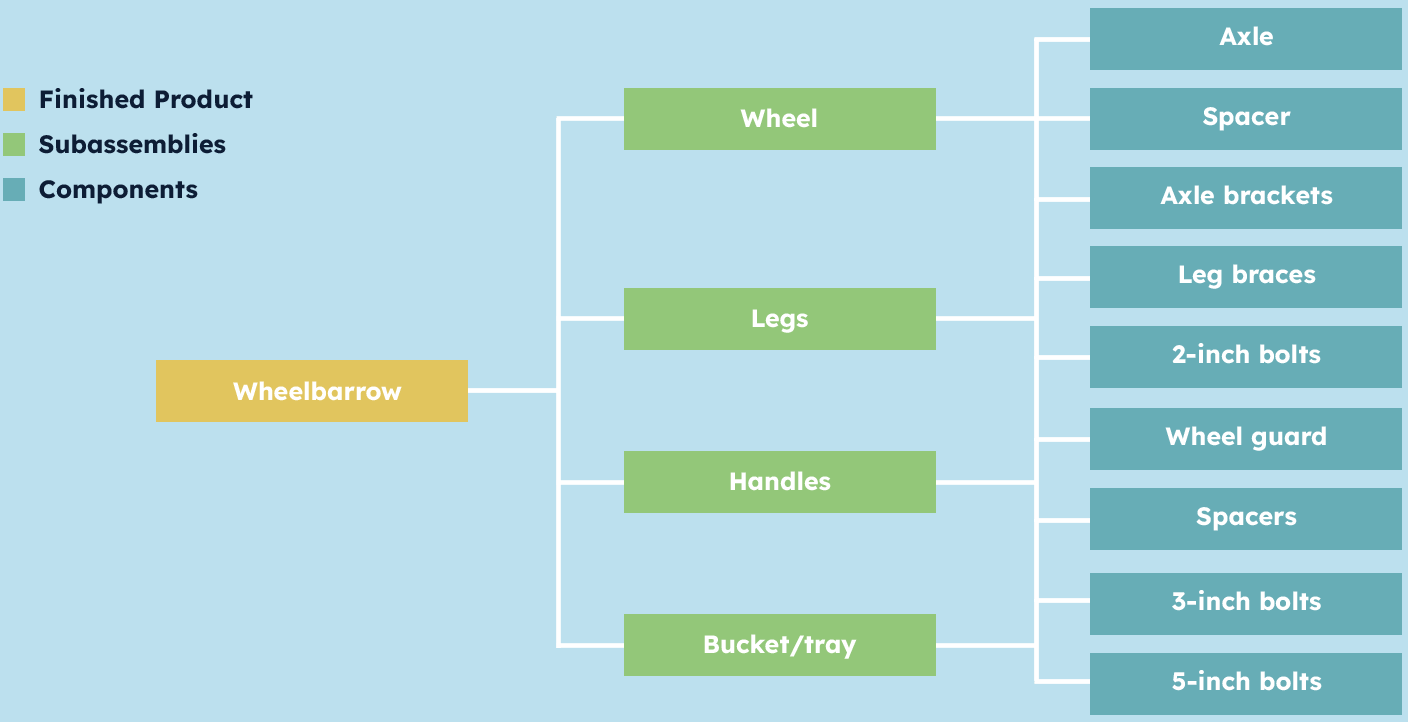

Any product that a company manufactures is supported by a bill of materials (or ‘BOM’). This shows all the raw materials or components needed to manufacture a product as well as the required quantities.

The diagram below shows a simple bill of materials. By looking at this, we can see the different parts and components that combine to make up the finished product.

Of course, not all products are so simple. Many products are made up of hundreds, if not thousands, of separate parts and components.

The photo opposite shows a visualisation of the Ford T Model at the Henry Ford Museum of American Innovation in Michigan, United States.

Lean manufacturing

‘Lean’ is a very important concept in manufacturing. Lean aims to improve efficiency by eliminating waste. In lean, ‘waste’ means any activity that consumes resources but provides no benefits.

Lean is a process that starts by identifying waste in a process and then eliminating it little by little until the process is as streamlined as possible.

There are 8 types of ‘waste’ associated with lean manufacturing. Click on the images below to learn more about them…

Lean can be applied to any area of manufacturing – whether it relates to planes, phones, or food.

Example careers in Production

Click on the buttons below to learn about some of the different roles in Production…

Did you know?

The UK is currently the 8th largest manufacturing nation in the world.

Defects

Defects are errors. Errors require time to fix. An aim of lean is to avoid mistakes or the production of bad quality goods.

Overproduction

Overproduction is caused by producing more or faster than is required. An aim of lean is to avoid producing any more than what customers need.

Waiting

Waiting is any idle time produced when 2 processes are not completely synchronised. An aim of lean is to connect processes well so that no time is wasted.

Unused Talent

Unused talent is when people with expertise are excluded from the process. An aim of lean is to use the most appropriate talent for the process.

Transportation

Transportation is the movement of materials from one location to another. An aim of lean is to avoid unnecessary steps in between processes to reduce travel time.

Inventory

Inventory is any item tied up in raw material, work in progress or finished goods. Inventory costs money until it is sold. An aim of lean is to store as little excess inventory as possible to reduce costs.

Did you know?

Motion is the movement of machines or employees between different processes. An aim of lean is to make motions as small or as easy to achieve as possible

Extra-processing

Overprocessing is to put more into the product than is valued by the customer. An aim of lean is to avoid doing any more than what customers want.

Make a note!

What does the acronym BOM stand for?

Production worker

Production workers manufacture goods and parts in industries like pharmaceuticals, food and drink, construction and engineering.

Average Salary: £22,000-£28,000 (or £1,833 – £2,333 per month)

In this role you could:

- Produce sample packaging to test different materials and designs.

- Run production trials.

- Make sure packaging meets quality standards and is safe.

- Work closely with product designers and production engineers.

- Work out ways to make packaging more environmentally friendly.

- Write technical reports.

Quality control assistant

Quality control assistants check that a company’s services or products meet necessary standards.

Average Salary: £20,000-£30,000 (or £1,666- £2,500 per month)

In this role you could:

- Make sure required standards and regulations are met.

- Inspect and test products or processes.

- Identify faults or errors.

- Record and tell other people about complaints and fixes.

- Design, review and update quality control policies.

Packaging technologist

Packaging technologists design and develop packaging for different products.

Average Salary: £23,000-£40,000 (or £1,916 – £2,000 per month)

In this role you could:

- Produce sample packaging to test different materials and designs.

- Run production trials.

- Make sure packaging meets quality standards and is safe.

- Work closely with product designers and production engineers.

- Work out ways to make packaging more environmentally friendly.

- Write technical reports.

Supply Chain Operations: Distribution

The management of how goods are moved, stored, and transported is known as logistics.

When we talk about logistics, we are referring to:

- Warehousing and storage.

- Transport and distribution.

Logistics activities take place at every stage in the supply chain. Suppliers, manufacturers, retailers, importers, and exporters all need logistics to get their goods from point A to point B.

Learn more about different functions that keep goods moving in ‘Introduction to Logistics’ and uncover a range of career opportunities.

Career Path Questionnaire

This simple questionnaire might help you to identify some career pathways that suit your personal interests and your skills. This questionnaire comes in 2 parts. The first part of this activity is a simple questionnaire.

Using the options in the table below, answer each of the questions by selecting a number in one of the columns, based on the following:

1 = Dislike a lot 2 = Dislike 3 = Don’t Mind 4 = Like 5 = Like a lot

Based on your personal interest and skills, you may be interested in the jobs shown in the highlighted section below.

Working with IT and projects

Roles explored in this course:

- Marine engineering technician

- Rail engineering technician

You may also enjoy other careers in engineering, information technology, and energy.

You scored

in this category.

Working with people and processes

Roles explored in this course:

- Transport and distribution clerk

- Database administrator

- Import-export clerk

- Customer service assistant

- Finance officer

You may also enjoy other careers in learning and development, human resources, and customer service.

You scored

in this category.

Working on your feet or outdoors

Roles explored in this course:

- Warehouse operative

- Heavy goods vehicle driver

- Forklift driver

- Ground handling agent

- Port operative

You may also enjoy other careers in manufacturing warehousing, airports, and sea ports.

You scored

in this category.

8 Steps to Get You Started

- Make a list of your personal strengths and interests

- Follow logistics companies on social media

- Check out the careers section in the library

- Speak with a career’s advisor

- Explore apprenticeship options in transport and logistics

- Look at the skills required for careers that interest you

- Create a portfolio of your favourite achievements

- Set and follow-up on career-related goals

Check Your Knowledge

So now you’re well on the way to understanding about the Supply Chain, answer the multi-choice questions below to see how much you really know.

Good luck!

Well done. You have successfully achieved the pass mark for this course. All the correct answers are now shown.

You haven’t achieved the pass mark on this occasion. Have another go.

You haven’t quite reached the pass mark for this course, but all of the correct answers are now shown. Please study these before moving on, or feel free to go back and look again at any of the pages of this course.